Grippers

Grippers

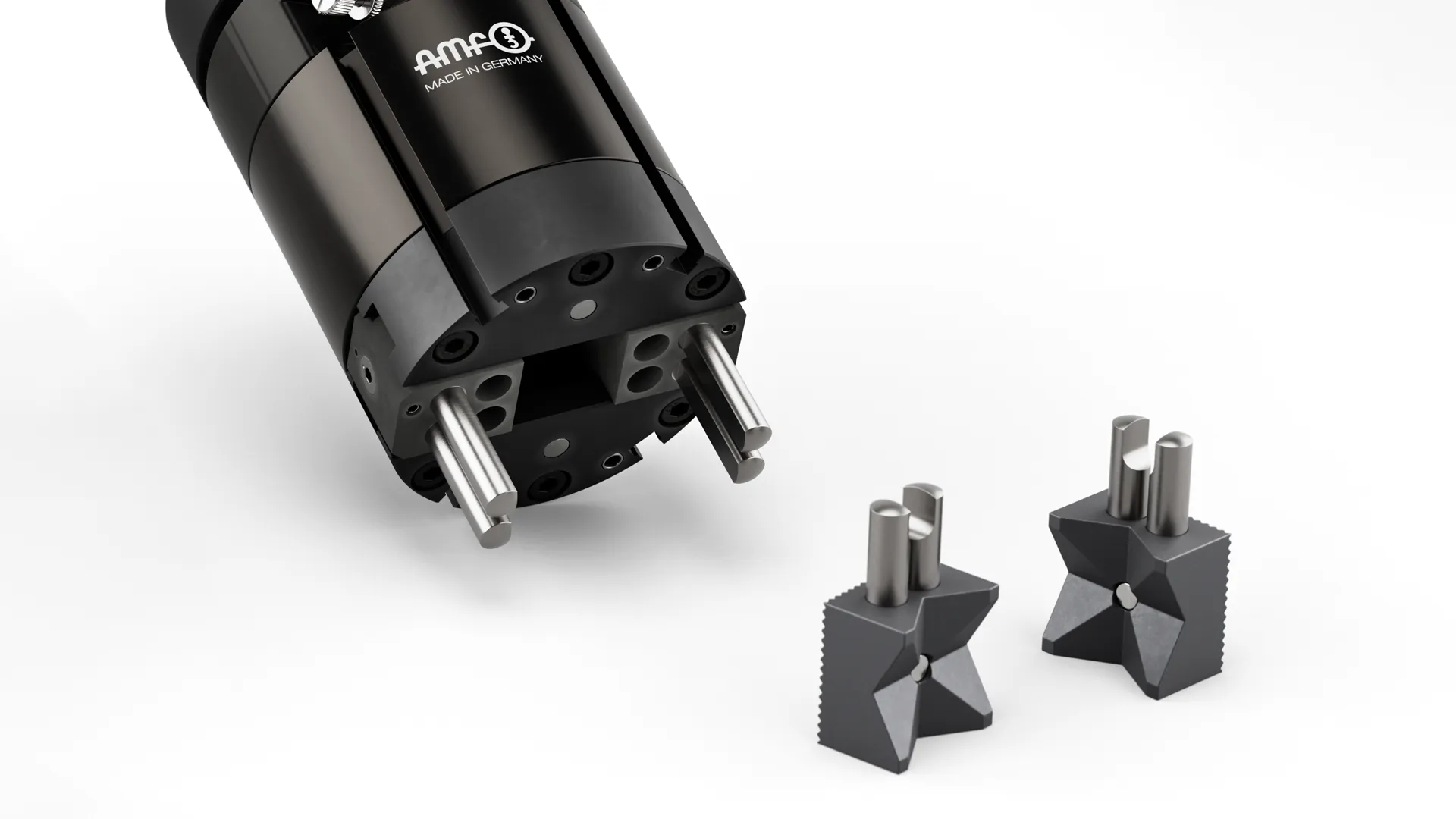

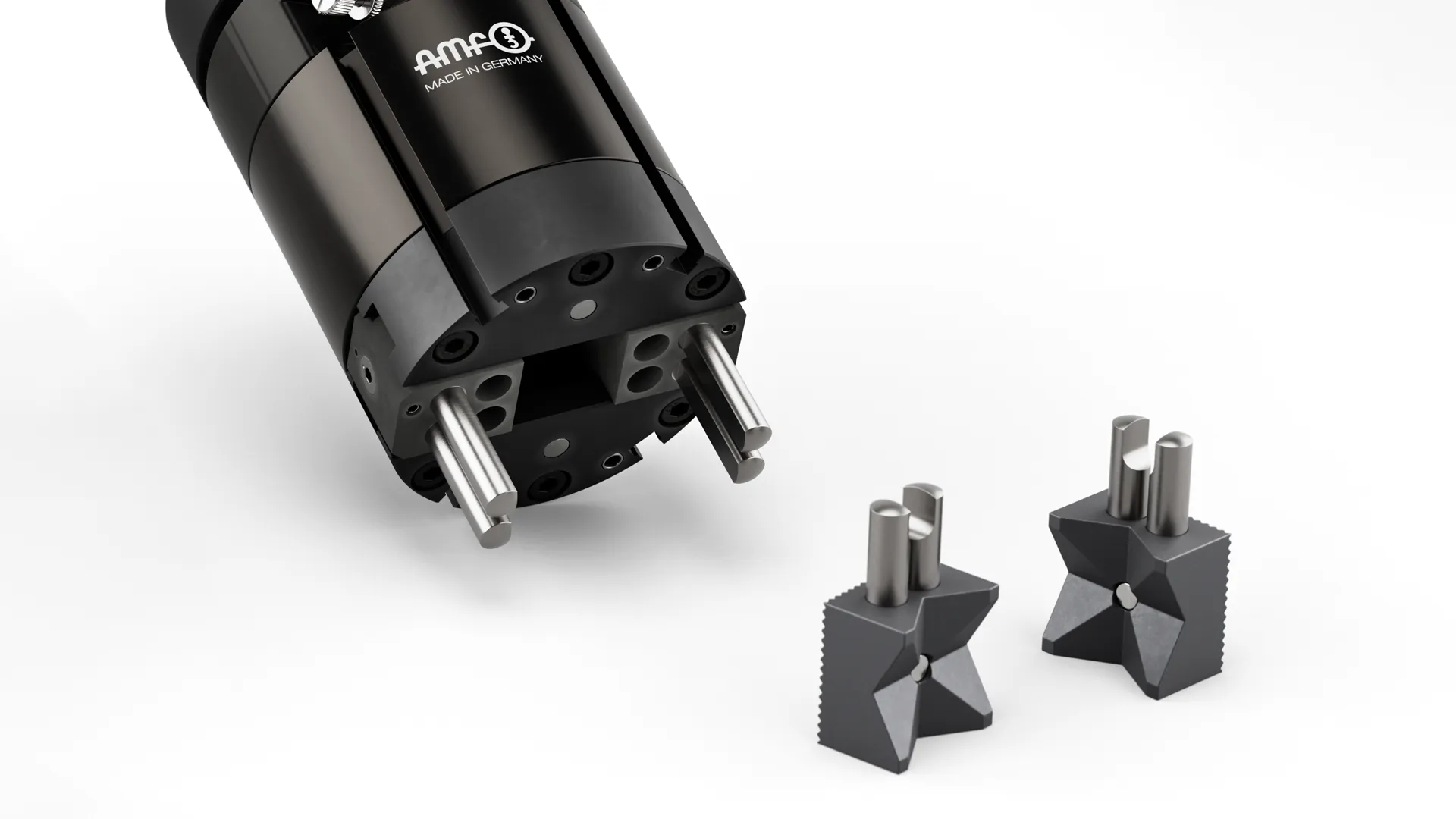

With sophisticated gripper technology, AMF offers a smart solution for getting started with low-cost automation. As an experienced manufacturer, we know what is important in automated production: our grippers reliably handle the loading and unloading of workpieces into the clamping device – enabling unmanned shifts around the clock. The result: more machine running time, less set-up effort and significantly increased efficiency.

Easy integration, more machine operating time

The gripping technology is the key to economical automation in production. As a manufacturer, we develop pneumatic grippers that can be seamlessly integrated into existing machine tools and ensure efficient, smooth processes – without any complex modifications.

Thanks to self-resetting counterbalance elements, the precise positioning of the workpieces is particularly gentle, which also reduces the load on the machine spindle. Different gripper inserts and modular variants enable a high degree of flexibility, even with changing workpiece geometries.

Your benefits at a glance

- High, adjustable gripping force for different workpiece weights

- Ideal for automated loading and unloading in CNC and milling machines

- Various types of grippers can be combined (e.g. inside and outside gripper)

- Overload protection to prevent damage

- Perfect complement to clamping technology and automation solutions

- Optimal for low-cost automation in series and single-part production

Whether machine building, cutting or medical technology – with AMF grippers, you can automate your workpiece handling precisely and economically. Easily integrated and ideal for any manufacturing process. Automation made easy – we show how it's done in the video!