Vacuum clamping systems

Vacuum clamping systems

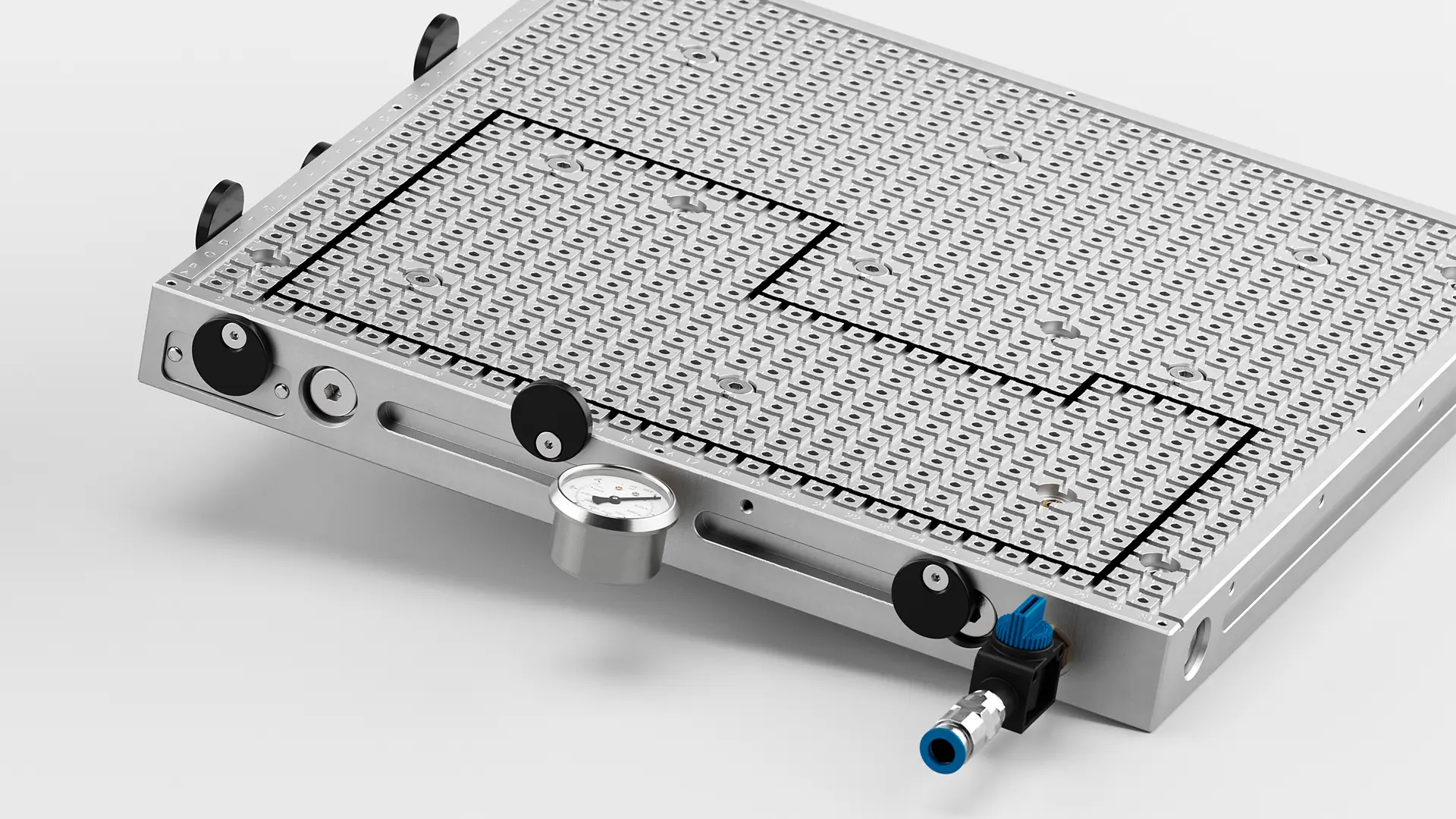

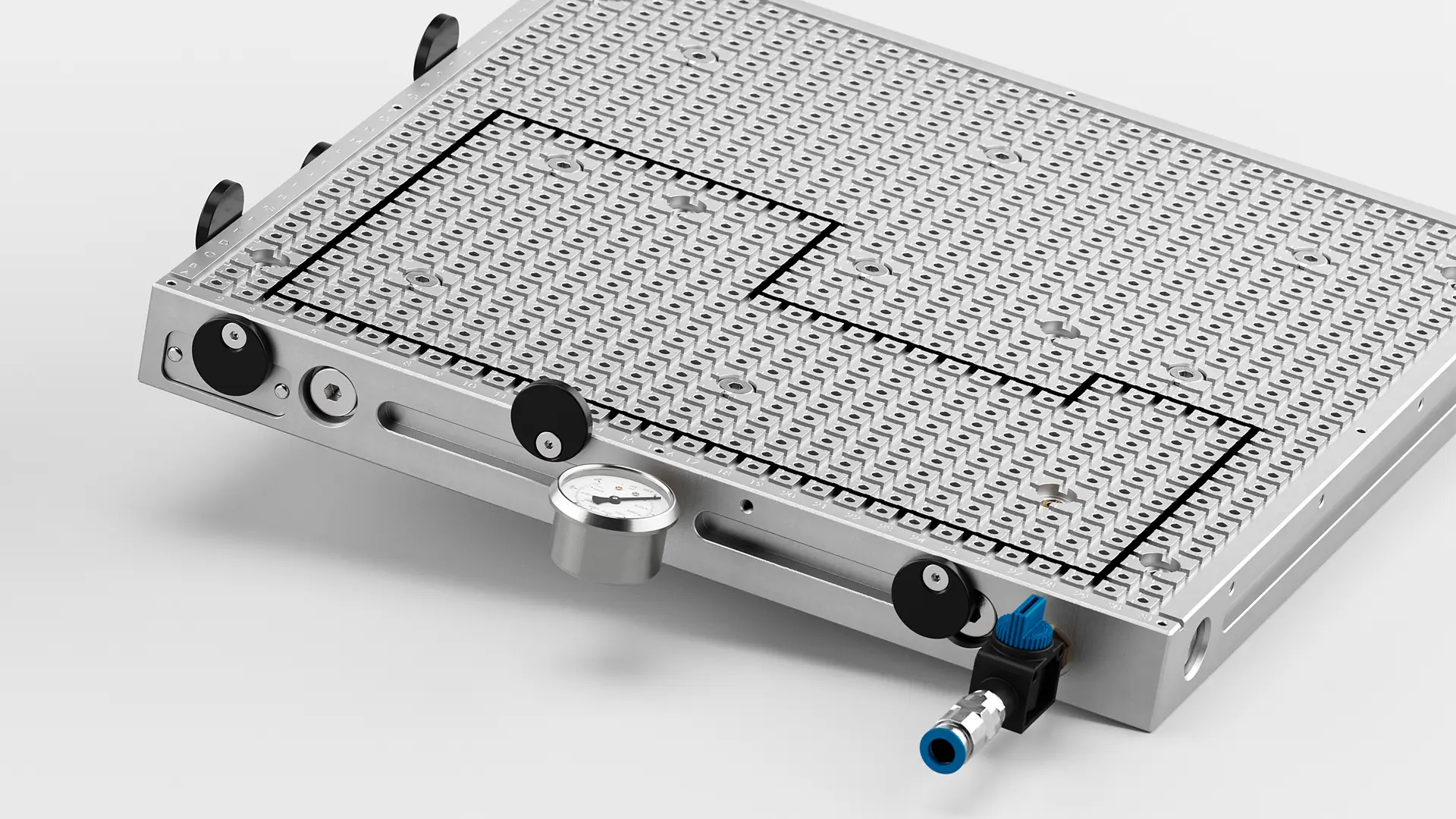

The sophisticated design of our vacuum clamping systems reflects our commitment as a manufacturer of cutting-edge technical products to permanently improve production processes – precisely, reliably and in a time-saving manner. They enable the fast and material-friendly clamping of workpieces and are ideal for 5-sided machining in CNC machining centres, milling machines or in fixture construction. By using vacuum, workpieces can be fixed in seconds – without the need for complex alignment or mechanical clamping equipment. Already available compressed air is sufficient to generate secure clamping with the AMF vacuum clamping plate. This ensures shorter set-up times and increased machine running times – a real advantage in modern production.

5-sided machining made easy – fast, gentle, precise

Our vacuum clamping plates enable the fast and secure fixing of a wide variety of workpiece geometries – including multiple parts simultaneously. The flexible system protects sensitive surfaces and guarantees uniform clamping force distribution through several suction points. Workpieces can be changed in seconds – ideal for single-part and series production.

When combined with the tried-and-tested AMF zero-point clamping system, this opens up additional automation options and saves valuable set-up time.

Thanks to our modular design and many years of experience as a manufacturer, we at AMF offer a flexibly expandable vacuum clamping system – with precisely fitting accessories such as adapter mats, adapter plates, height-adjustable surfaced-mounted blocks, vacuum pumps, liquid separators, and other sophisticated components.

Our experts will gladly advise you – including on individual requirements, special designs or tailor-made project solutions. Contact us now!

Your benefits at a glance

- High holding forces through precise vacuum

- Simultaneous clamping of several workpieces

- Precise positioning without manual alignment

- Gentle fixing of sensitive components

- Integrated mounting holes for the AMF Zero-Point-System

- Energy-efficient thanks to Venturi nozzle

- Ideal for CNC machining, toolmaking, prototyping & series production

Watch the video to see how you can use AMF vacuum clamping plates and the zero-point clamping system to automate your set-up processes, efficiently fix workpieces and thus significantly increase your productivity – quickly, precisely and gently.