Applications

With a sense for exciting solutions

Many projects involve much more in the production process than the use of innovative clamping technology products. With increasing complexity of the requirements, the demand for the holistic nature of the solution is increasing, too. It is precisely such challenges that constitute the heart of the work for our engineers and designers.

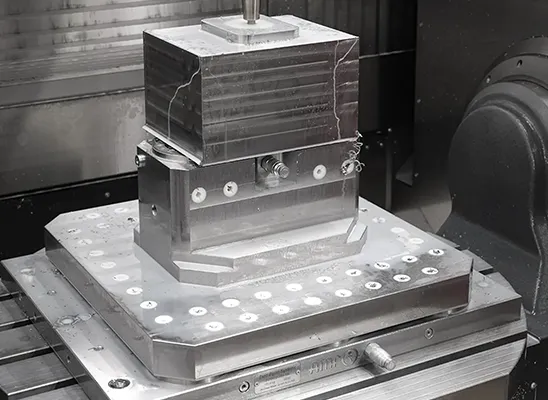

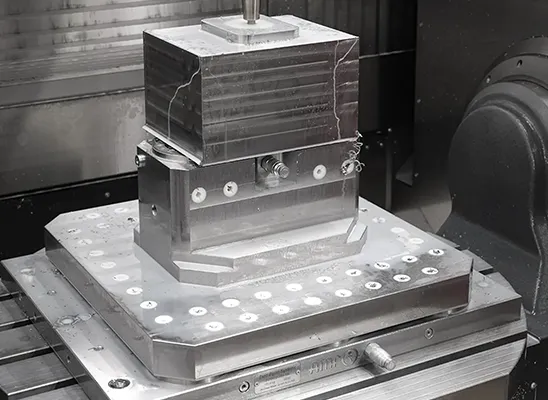

Efficiency in set-up achieved across all processes

A manufacturer of systems and components for plastics processing produces high-precision assemblies for granulation and filter systems. To ensure that these components function reliably, they must be manufactured to the tightest tolerances. In order to keep machine running times high and set-up times low, the manufacturer has been relying on modular workpiece clamping technology from AMF for many years. Zero-point clamping systems in particular contribute to making production efficient and flexible across all processes.

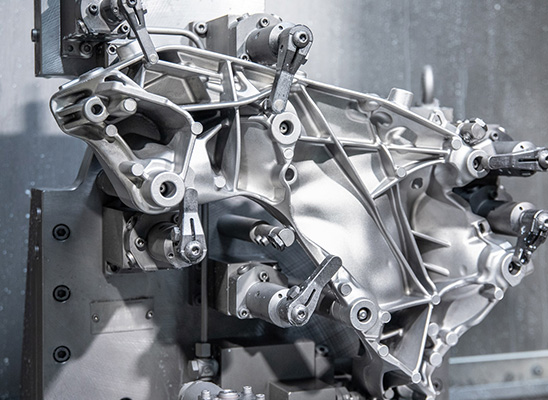

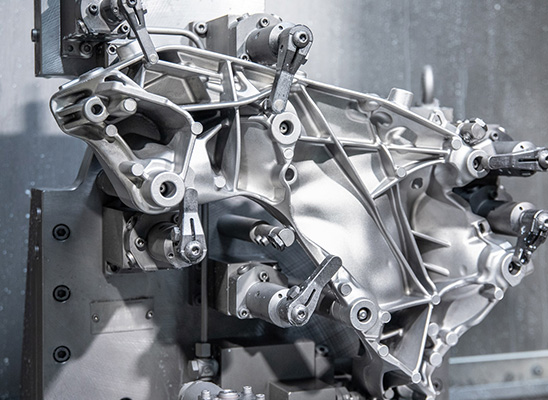

Clever fixture solutions for demanding small series

A manufacturer of precision pumps produces components for high-performance applications in the automotive and motorsport sectors. Small series with high requirements for tolerance, process reliability and repeatability are part of everyday business. To enable these to be manufactured economically and automatically, AMF developed custom-fit clamping devices. These enable the unmachined parts to be clamped securely and lay the foundation for efficient, largely unmanned production.

Optimum clamping solution through solution-orientated production partners

Just in time for the largest order in the company's history, a specialist mechanical engineering manufacturer comes up with the idea of using vacuum clamping technology. This allows many aluminium workpieces to be produced in a single clamping operation, where otherwise individual blanks had to be clamped. With this, the clamping experts at AMF have virtually pulverised the set-up time.

Fast and precise to the best surfaces

When a well-known original equipment manufacturer of machines needed to replace an old vertical lathe, a new turning/milling centre now provides the necessary requirements and capacities for the complete machining of a wide range of large workpieces. For the manufacturing of the mostly customised products, zero-point clamping systems from AMF pulverise the clamping processes and set-up times. And precision as well as surface quality increase exorbitantly.

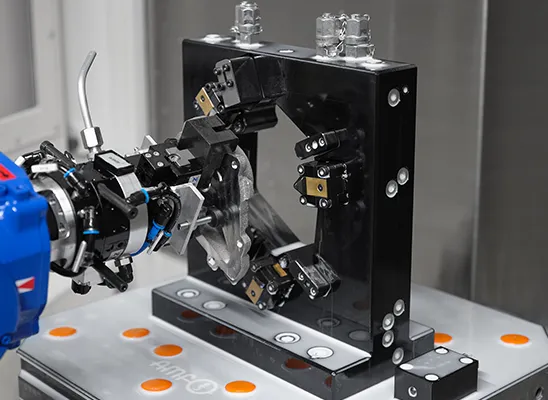

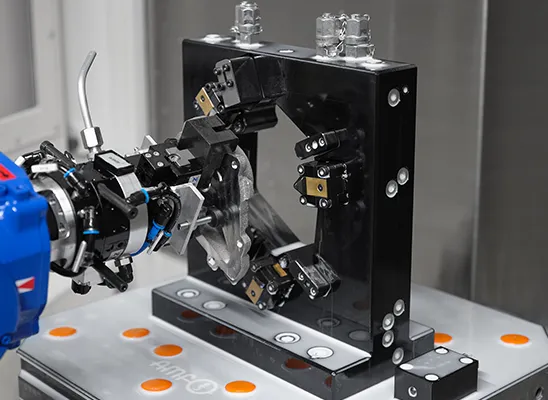

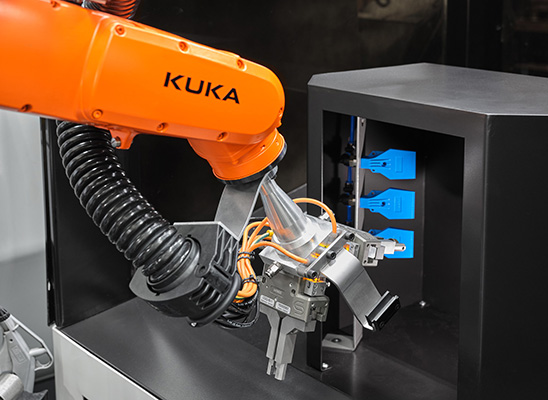

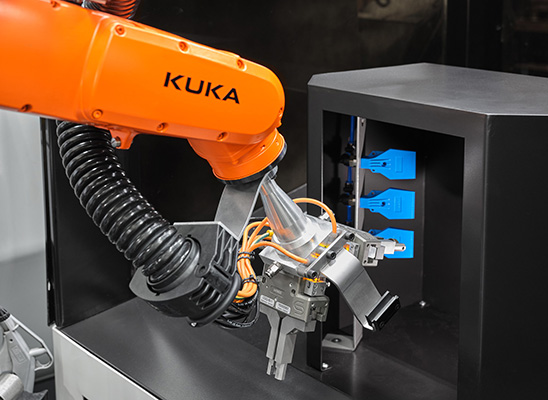

AMF Smart Automation loading system increases the depth of production for users and counteracts the shortage of skilled labour

The first user of the new robot loading system for automated workpiece handling presented at EMO 2023 is already "shockingly in love" after just a short period of use. The smart, slim and flexible loading cell with very little space requirement not only ensures greater productivity, but in-particular, for more independence. Attached to an existing lathe, it ensures reliable and unmanned continuous loading and unloading. And thanks to its smart sister opposite, the parts arrive spotlessly clean for further processing.

Manufacturing times are just pulverised

Innovation and investment in workpiece clamping technology pulverise earlier manufacturing times. The individual clamping solutions from AMF play a decisive role. And so the core components of sheet-fed offset presses are today produced flexibly and with high process reliability using much fewer clamping procedures than in the past. Today, only three clamping procedures are needed, where before eleven were necessary.

Rapid change for the lifelines

A premium automotive supplier in southern Germany produces many variants of an important connection part in e-mobility. Linear machines ensure economical production of these small series. The machine tables are equipped with AMF zero-point clamping modules so that the frequent tool changes of the multi-variant series can be carried out quickly and reliably. In this way, the tools can be set up in a time-saving and economical manner. This gives premium electric vehicles from Stuttgart a further boost.

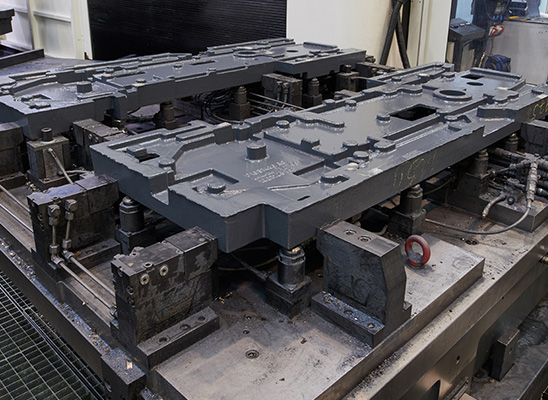

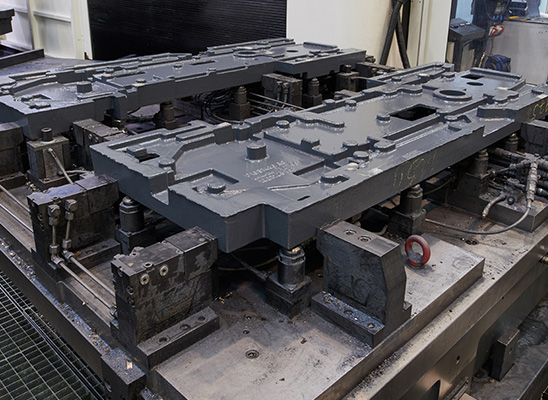

Clever approach to zeroing flexible fixtures

A mid-sized Hungarian company manufactures aluminium die-cast parts and then processes them into highly relevant components for the who’s who of the automotive and large-scale industries. A multi-purpose system for workpiece clamping on the machine table is created from a clever fixture construction and efficient zero-point clamping technology from AMF. It is so flexible that the machines can be set up quickly for both mass production and small-series production. Even the most prestigious customers are impressed.

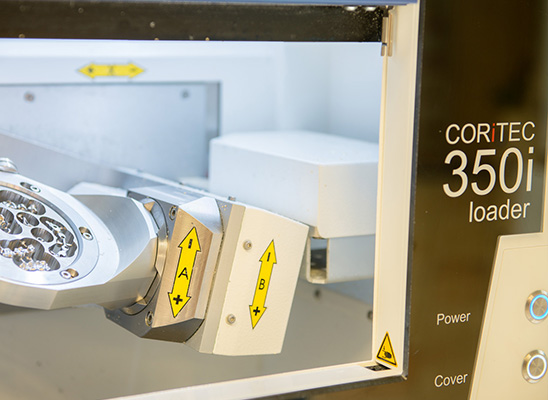

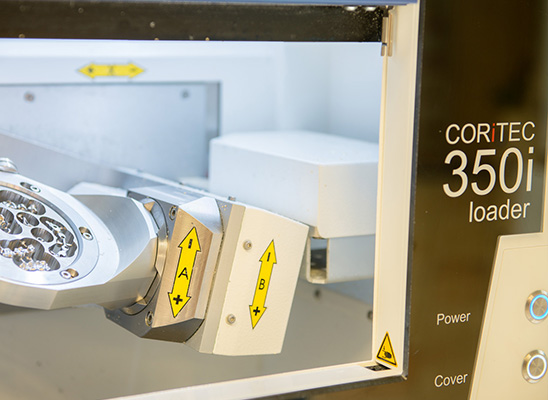

Fully automatic production of implants

A manufacturer offers machines for 5-axis simultaneous machining in the dental sector. Automation in milling is possible with AMF zero-point clamping systems. This reduces costs, increases productivity and ensures exceptional precision for compact machine dimensions.

Germanys next Top-Modell

Long before a new car model hits the road, it can be seen and touched at a Bavarian model builder – at least, if it weren’t top secret. The experts sculpt whole vehicles from aluminium blocks as 1:1 models for many OEMs. Thanks to intelligent zero-point clamping technology from AMF, aluminium blocks weighing multiple tonnes are cut with strong process reliability – fast, flexibly, and with repetition accuracy.

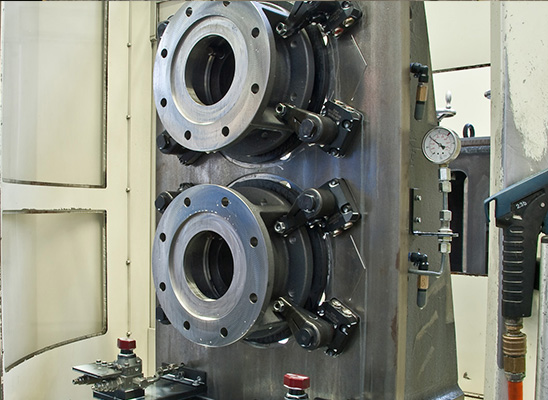

Well-rounded

One of the technology and world market leaders in equipping pipe, wire, and rod rolling mills is optimising its production. With AMF zero-point clamping systems, the number of set-up procedures has dropped from 9 to 3, and set-up times have fallen by over 80%. The new flexibility also reduces replacement part delivery times and permits worker-free shifts.

Fervent admirers

A global market leader in machine building restructures its production in order to reduce set-up times. Since the employees are involved at an early stage, the modern zero-point clamping systems from AMF open the door for an even more productive future. Nobody had expected this effect.

Complete solution around the zero point

As a commercial vehicle company that has automated the production of hydraulic parts with machining centres and one loading system, the availability of machines has increased significantly. The retooling during productive cycles becomes a bottleneck, however. AMF is developing a complete solution with hydraulic clamping elements and zero-point clamping technology, which is flexible and fast.

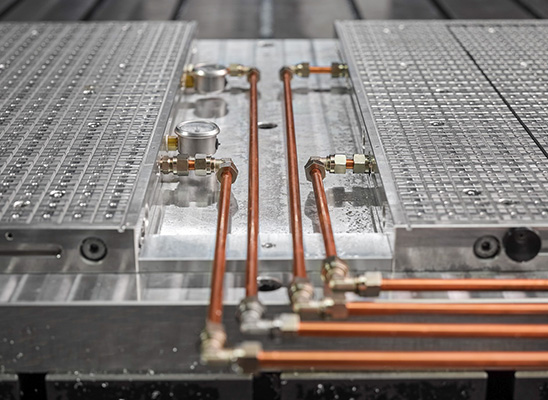

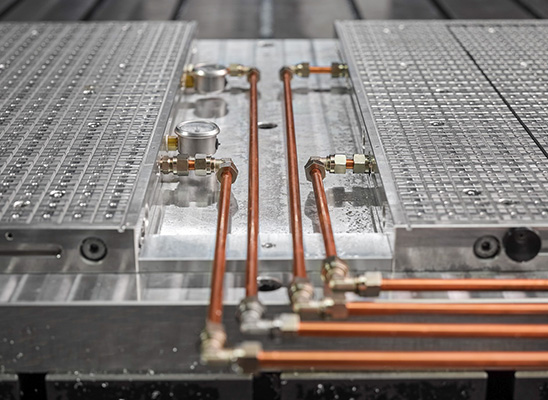

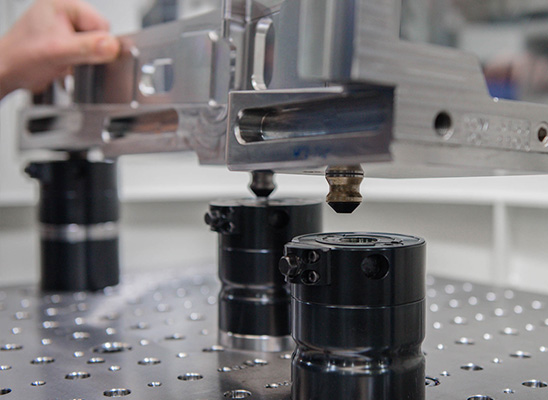

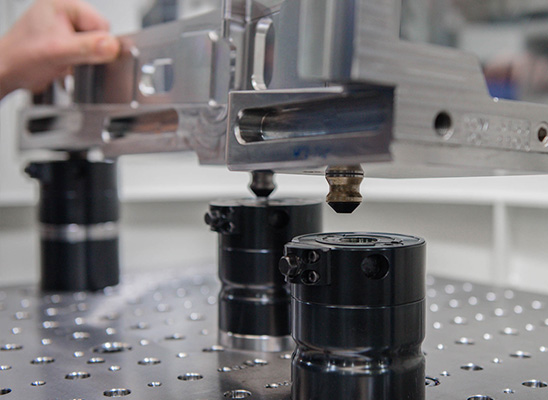

Back and forth below 2 µm exactly

A technical university produces the smallest plastic parts - prototypes of the future. During production of the moulds and tools, AMF ensures maximum flexibility with minimum tolerances. The change between two milling centres is achieved with incredible accuracy. Behind this lies a secret.

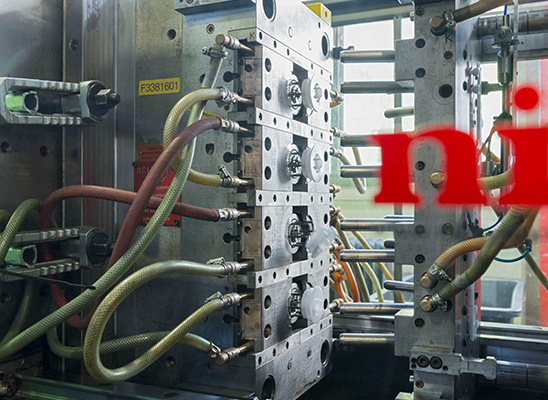

From crocodiles and sports cars

The flexible owner of a medium-sized company produces plastic parts with a variety of injection-moulding processes. To ensure efficient set-up time and rapid changing of the injection moulds, he relies upon adjustable and quick-mounting clamping jaws from AMF. The icon of sports car production also benefits from this competitive pace.

Disarm

A manufacturer of electrical actuators for fittings starts campaigning against excessively high set-up times. Productivity during difficult and easy cutting work improves drastically with the clamping experts from AMF. The establishment of a labour-intensive third shift can still wait.